Daphne Technology develops filtration systems that reduce greenhouse gas emissions. Designed for land-based and maritime applications, its innovative solutions are aimed at the industries facing the biggest decarbonisation challenges. After sulphur oxides, methane and CO2, the company plans to work on nitrogen oxide and nitrous oxide capture.

Turning marine pollution into fertiliser was Daphne Technology’s initial ambition. The company adopted the principles of the circular economy with a view to reducing emissions of, among other things, sulphur oxides (SOx) and nitrogen oxides (NOx) from ship engines. This technology developed to purify and recycle exhaust gases may not yet have conquered the oceans, but alongside this, Daphne Technology is continuing to develop its filtration system for land-based applications, also adapting to the ever-increasing use of natural gas (methane, CH4)4in place of diesel in numerous industries.“In addition to maritime transport, our systems are designed for oil and gas production sites, mines, energy producers, cement works and other industrial activities where reducing CO2 emissions is a challenge,”says founder and CEOMario Michan.

The company’s SulPure® process, which reduces sulphur oxides emissions by up to 99.1%, was shown to be effective first in a land-based and then in a maritime prototype. This has enabled Daphne Technology to launch several feasibility studies in Europe (for applications in the cement industry) and Brazil (in the energy production sector). Meanwhile, its SlipPureä technology has passed muster in a full-size demonstrator, achieving methane emission reductions of up to 75%.“It’s less often mentioned, but the global warming potential of methane is actually 28 times greater than that of CO₂,” says Mario Michan. In 2023, Daphne Technology set up the first industrial demonstrations of this technology in the United States, in land-based and maritime applications. And this pioneering company intends to roll out its solutions all over the world.

Between 2021 and 2022, Daphne Technology raised CHF 23 million in capital funding from investors including Trafigura, Shell Ventures, AET Tankers and J.P. Morgan. This capital is set to finance its further technological and commercial development, including work on reducing CO2 emissions2 from methane flaring at oil extraction sites, in partnership with Saudi Aramco.“We already know how to capture sulphur oxides and methane, and we are on the brink of being able to capture CO2,”says CEO Mario Michan. From 2027 onwards, the company will turn its attention to filtration systems for nitrogen oxides (NOx)2and nitrous oxide (N2O), a powerful greenhouse gas resulting from the use of various substances including nitrogen derivatives of hydrogen such as ammonia3(NH3).“Our aim is to combat global warming by developing solutions to reduce emissions of all the greenhouse gases,”he concludes.

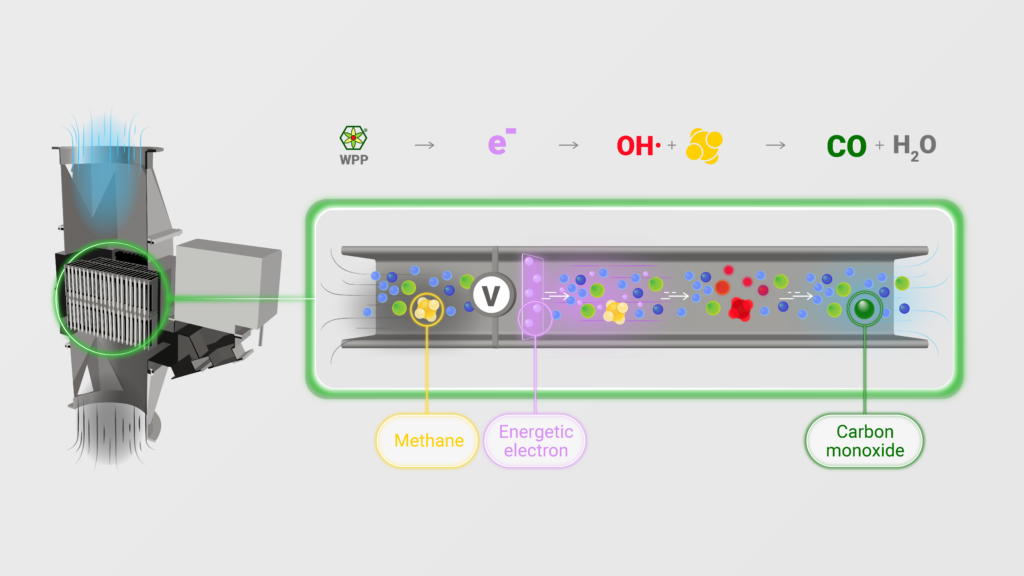

Photo caption : The plasma generated in the cartridge as a result of the WPP Power Supply produces energetic electrons in the exhaust gas. These electrons interact with the exhaust gas to produce highly reactive species, including hydroxyl radicals. These hydroxyl radicals react with methane, reducing the overall content of methane in the exhaust gas. The only by-products are carbon monoxide and water.