Superior performance, reduced maintenance, natural fluids and no oil. That sums up the ammonia compressor developed by ZERO-C. With this innovative, cutting-edge technology, the refrigeration specialist is helping to bring down the carbon footprint of buildings, industry and district heating networks.

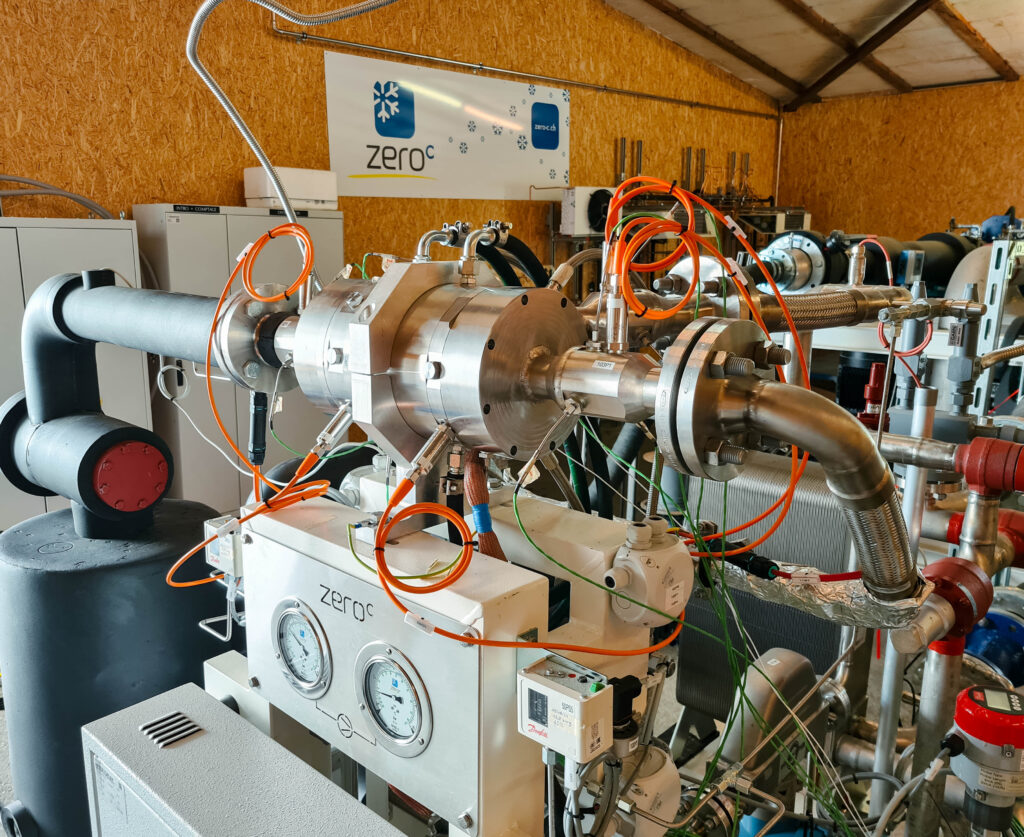

ZERO-C, the acknowledged specialist in industrial refrigeration and high-power heat pump technology, manufactures its own compressors and offers its customers a comprehensive service, from project design to complete installation. And for more than 10 years, this ground-breaking company has been using only natural fluid refrigerants with a very low environmental impact. ZERO-C developed the first thermal network to use CO2 on the Energypolis campus in Sion. In 2017, Pierre-Alain Giroud and his colleagues began developing an ammonia compressor (NH3). The resulting prototype, which has been on the test bench since 2022, is the perfect example of disruptive technology.

“Ammonia is the natural fluid refrigerant with the best thermodynamic performance at low pressures,” says Pierre-Alain Giroud. “It’s widely available and also the most energy-efficient.” In addition, ZERO-C’s high-speed compressor has the advantage of generating very little friction. By keeping the number of moving parts to a minimum, this technology does away with the need for oil, simplifying maintenance considerably. “It’s the only compressor of its kind in the world,” says Pierre-Alain Giroud proudly. The machine, technologically advanced but simple in the way it works, produces little vibration and is very quiet. A twentieth of the size of the models currently on the market, this ammonia compressor is also up to 16 times lighter, while performing up to 20% better. Each unit has a power output of around 100 KW, and several compressors can be mounted in series as required.

“We are developing a complete range of ammonia-based compressors, for all temperature requirements and for applications in buildings, industry and district heating networks,” adds Pierre-Alain Giroud. “These are major decarbonisation markets.” One of Switzerland’s big agri-food companies is watching ZERO-C’s prototype developments very closely and has made no secret of its intention to buy its first commercially available compressor.

And ZERO-C has other developments in the pipeline too: one of its customers is trialling a second type of compressor that uses water vapour as the refrigerant. At the same time, the company is raising the capital it needs to begin industrial production. ZERO-C is targeting the markets in Switzerland, Europe, the United States and Japan. “We offer a product with a high added value that ties in with the global aspiration to improve energy efficiency. Our ambition is to provide a solution with the lowest possible impact over the longest possible period,” concludes Pierre-Alain Giroud.